This article includes step-by-step instructions with photos for how to fix a problem with the iRobot Roomba Cleaning Head Module. This fix is a repair for modules when the brushes have stopped moving due to the build up of hair and debris in the gear box. If you’re handy at all, this should be a pretty easy fix. Obviously, this won’t necessarily resolve the problem in all cases. Be careful and do this at your own risk.

The Cleaning Head Module on the 500 Series iRobot Roombas are a sore spot for many robot owners. The problem being errors and maintenance problems caused by the slow accumulation of hair and debris in the gearbox of the Cleaning Head Module. The problem affects basically all the 500 and 600 series Roombas. So this means the 610 Professional, the 570, 572, 560, 562, 532, 530 and 510. As you can see, this includes the Pet Series Robot vacuum cleaners. I’m pretty sure that the 400 Series, 4000 Series, and earlier are also affected. As mentioned in my 780 review, the design of the Cleaning Head Module on the 700 Series Roombas is clearly different, but only time will tell if it has the same problems.

What happens is that the gear box of the Cleaning Head Module collects hair and debris over time and gets jammed up so that the brushes don’t turn while the robot vacuum is cleaning. As a result the ability of the Roomba to clean properly is affected, and the robot may also give errors or refuse to work. While it is possible to order a Roomba 500 600 700 Series Cleaning Head Replacement, you might be able to solve your problem by following the instructions, below.

First remove the dust bin. Then remove the sidebrush by unscrewing the screw in its center and then pulling the side brush off. Next unscrew the four screws that hold the bottom panel on. They are the screws with the little triangle arrows next to them. These screws don’t come all the way out. You just need to unscrew them until they are loose and the panel can lift off.

With the bottom panel off, you can see the Cleaning Head Module. There are four more screws holding this on. There are two at the top of the module, next to the corners of the APS battery. The other two screws are near the bottom on either side of the module. The Cleaning Head Module looks kind of like a rectangular box with two arms coming off of it. These screws, like screws that hold the panel on, don’t screw out all the way, so you only have to screw them out enough until you can lift the module out of the body of the robot.

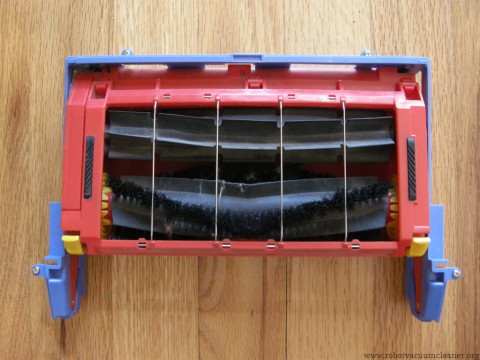

Here is the Cleaning Head Module out of the Roomba. The gearbox on this module is on the left side here, and is in the red part of the module. So you see there where the brushes go into the left side? That’s where the gear box is. The gearbox drives the brushes. That’s also where the hair and debris gets into the gearbox. Getting into the gearbox is a little more work. Here’s how you can do it.

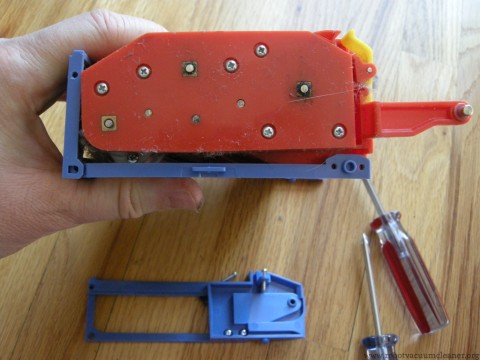

Pick up the module so that it’s on one end with the gearbox end pointing up towards you. Here you can see that there are four more screws which are holding the blue side of the module on. We need to take the side off so that we can get to the red part. So unscrew these four screws and lay them in one place.

Here’s the cover on the gearbox. As you can see, we have six more screws that need to be removed and then we can take the side off. Remove and place the screws in a spot away from the other screws you pulled out previously, so that they don’t get mixed up.

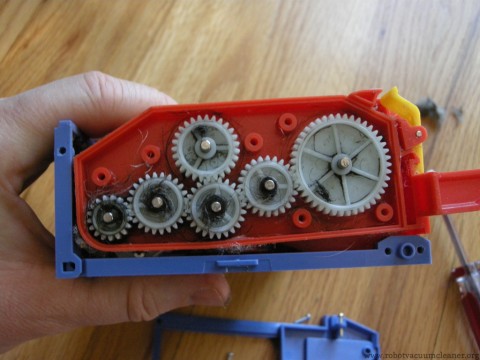

And here’s what might be in your Roomba’s Cleaning Head gearbox. My Roomba was functioning just fine, even with all this hair and debris, but you can see that there is some accumulation and that eventually this might render the module inoperable.

While doing this cleaning, I only pulled one gear out at a time so that I wouldn’t lose the proper placement of the gears. I would guess that a person could probably take the gears and place them on a piece of paper with numbers to keep them straight, or find another way of keeping them in order, but I like to keep things simple. So what I would do is remove one gear, pull the hair off of it, and then remove any hair that was under it inside the gearbox.

It bears mentioning that the gearbox also contains a film of lubricant, and depending on your situation, you might be able to get away with just pulling out the hair and leaving most of the lubricant still in the gearbox. Not all kinds of lubricant are safe to use with plastic parts. If you know for a fact that you have a lubricant that is safe to use with plastic, then go ahead and really clean that gearbox out, and then put a little lube back in there. Otherwise, I suggest just doing your best to remove the hair and not wipe the gearbox out. (Note: Your local Radio Shack probably sells a plastic safe gel lubricant which would be appropriate.)

Here’s more area to clean. It’s worth noting that the engineers at iRobot have reinforced the plastic with brass for the holes that need it. I have found instructions online for boring out the insides of the gears in these gearboxes and installing gear bearings, but really, that’s something that a person shouldn’t be doing unless they have access to the proper tools for the job. Obviously, a metal gear train with bearings would be ideal. But nylon, stainless steel and brass have been used to make durable gear trains for a long time and in my humble opinion, the engineers at iRobot have created a suitable consumer-grade gear train. The problem is the holes for the brushes, not the gears themselves.

Once you’ve got the hair and fuzz and everything else out of the gearbox, carefully put it all back together again, and reassemble the robot following the instructions the other direction to assemble all the parts.

Here’s what I pulled out of this gearbox. I did this for the sake of demonstration, so if your Roomba’s brushes have stopped moving, I’m betting that you’ll be pulling a lot more than this out of your robotic vacuum.

Awesome! I was about to order a new Cleaning Head Module from iRobot. You inspired me to try cleaning the gearbox instead. Perfect! Took 15 minutes and was totally easy. Works perfectly now. Thanks for posting this! Jim.

Thanks for stopping by! I’m glad this was helpful.

I’m curious if there are any belts used to turn the brushes. My Roomba stopped working and a day or so later I found a broken rubber belt on our floor. I assumed it was from the Roomba but I’ve looked at several sites and see no mention of it. Your tutorial looks great, will try it out this weekend.

Nick

I don’t think there’s a belt in there. It’s a gear train. There is a strap that keeps the motor in place somehow, but it doesn’t look much like a belt. Anyways, hope the instructions help you!

Thanks, worked like a charm and got rid of the thunking problem on my Roomba 560

Glad to hear it!

Thanks for the guide unfortunately it didn’t work for me so looks like it’s a new cleaning head!

Sorry about that. It was worth a try!

THANK YOU THANK YOU!!!!

this worked wonderfully, and was all the info i needed!! I knew the gear box was where I needed to clean out, but couldn’t figure out how to get there. Thanks!!

Any specific recommendations for plastic-safe lube?? I got rid of the clicking noise & roomba working well, but I am hearing a new (kinda rough/scratchy noise), and think maybe I cleaned out too much without adding more lube.

Thanks again!

Here’s something on Amazon. Plastic Safe Multipurpose Lubricant I would bet, though, that your local Home Depot, Lowes, or Radio Shack would have something. Good luck!

I would bet, though, that your local Home Depot, Lowes, or Radio Shack would have something. Good luck!

Glad we could help.

Worked like a charm. Thanks!!!!!!!!!!!!

I have a 532 Pet series with a green cleaning module that exhibited the “thunking” sound. Unlike the blue module, there are no screws holding the gearbox to the outer casing of the module. Instead, it’s held by flexible arms that I gently pried apart to get to the gears. However, the motor is attached to the outer casing, and there’s a drive cable that runs from the motor to the gear box. It’s got just enough length so I could pull out the gear box, unscrew the 6 screws off the cover and perform the cleaning. I’d post photos, except it was NC-17 filthy! Thanks for the article – saved me from buying a new module.